N-Tetradecylphosphonic Acid (N-TPA) is a versatile phosphonic acid compound used in the functionalization of materials. It plays a crucial role in enhancing the surface properties of different substrates.

This article explores how N-Tetradecylphosphonic Acid works, its benefits, and practical applications in various industries, particularly in coatings and surface treatments.

What is N-Tetradecylphosphonic Acid and How Does It Work?

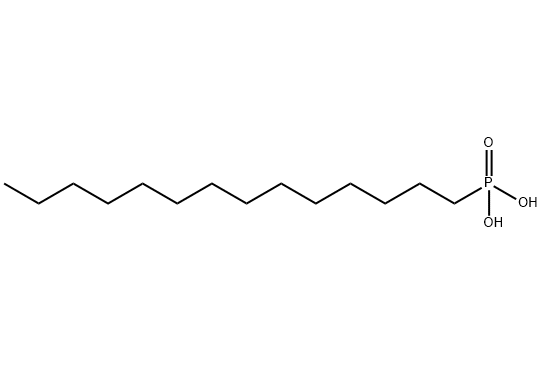

N-Tetradecylphosphonic Acid is a long-chain alkyl phosphonic acid that contains a hydrophobic, tetradecyl group. This chemical is widely used for surface modification because of its ability to form strong bonds with a variety of substrates, including metals, glass, and polymers.

When applied to a material's surface, N-Tetradecylphosphonic Acid forms a self-assembled monolayer, creating a protective coating that enhances the material's resistance to environmental factors such as moisture, corrosion, and chemical exposure. This bond is highly stable, making N-Tetradecylphosphonic Acid an ideal choice for functionalizing materials in harsh conditions.

Benefits of Using N-Tetradecylphosphonic Acid in Material Functionalization

The key benefits of functionalizing materials with N-Tetradecylphosphonic Acid include:

- Improved Durability: The hydrophobic nature of N-Tetradecylphosphonic Acid helps in making surfaces resistant to water and corrosion, significantly extending the lifespan of materials.

- Enhanced Surface Properties: By forming a monolayer, N-TPA improves the surface energy of materials, making them more suitable for applications requiring specific surface characteristics like adhesion and wetting behavior.

- Versatility: It can be used on a wide range of materials, from metals and ceramics to polymers and glass, making it an excellent choice for various industries.

- Eco-friendly Option: N-Tetradecylphosphonic Acid provides an environmentally friendly solution by reducing the need for harsh chemicals and additives in material processing.

How N-Tetradecylphosphonic Acid Enhances Surface Properties

N-Tetradecylphosphonic Acid is particularly effective in improving surface characteristics such as wettability, adhesion, and resistance to contaminants. This is due to its ability to interact with the material’s surface at a molecular level. By forming a stable monolayer, N-TPA can change the surface's energy properties.

For instance, it is commonly used to improve the adhesion of coatings on metals or polymers, making them more resistant to wear and tear. Additionally, it can also enhance the water repellency of surfaces, making them ideal for use in products exposed to moisture or harsh environmental conditions.

Applications of N-Tetradecylphosphonic Acid in Coatings and Adhesives

One of the most common uses of N-Tetradecylphosphonic Acid is in coatings and adhesives. When used in these applications, N-Tetradecylphosphonic Acid enhances the adhesive strength of coatings, ensuring they adhere better to the material substrate. This is particularly important in industries such as automotive manufacturing, aerospace, and construction, where coatings must withstand extreme weather conditions, wear, and exposure to chemicals.

N-Tetradecylphosphonic Acid can also be used in the preparation of anti-corrosive coatings for metals, protecting surfaces from degradation and extending their service life. This functionality is vital for industries like oil and gas, where equipment is often exposed to corrosive substances.

Common Industries Using N-Tetradecylphosphonic Acid for Material Treatment

Several industries benefit from the material functionalization provided by N-Tetradecylphosphonic Acid.

Some of the most notable applications include:

- Aerospace: In aerospace manufacturing, N-Tetradecylphosphonic Acid is used to improve the durability of metal components and prevent corrosion, especially in aircraft exposed to extreme environmental conditions.

- Automotive: In the automotive sector, N-TPA is used to enhance the surface properties of parts and coatings, improving wear resistance and longevity.

- Electronics: N-Tetradecylphosphonic Acid is employed to modify the surfaces of semiconductors, improving their performance and resistance to environmental stress.

- Marine: Coatings with N-Tetradecylphosphonic Acid are used in marine applications to protect metal surfaces from seawater corrosion and to provide water-repellent properties to boat hulls.

- Medical Devices: In medical device manufacturing, N-TPA can be used to create non-stick, corrosion-resistant surfaces on equipment that come into contact with bodily fluids.